ProductsContact Probes

What is a Contact Probe?

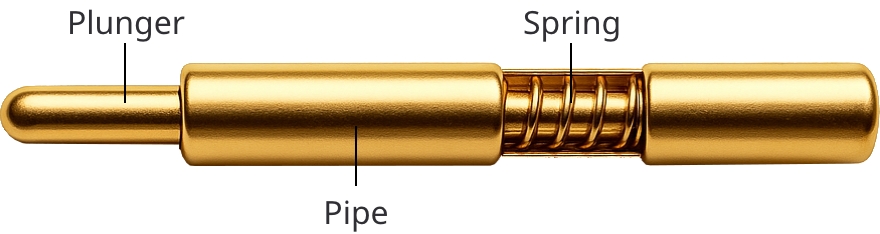

Also known as pogo pins, probe pins, or test probes, contact probes are essential components in electrical testing throughout the electronics industry. Whether you’re inspecting semiconductor wafers, packaged devices, FPD displays (LCD/OLED), or verifying continuity on PCBs and components, contact probes play a key role in ensuring test accuracy and reliability.

But precision isn’t just about making contact—it’s about maintaining consistency. That’s where Seiken’s deep engineering expertise makes a difference. From material selection to ultra-fine machining and advanced surface treatments, we deliver probes designed for your specific testing environment—whether it involves high temperatures, non-magnetic conditions, or high-current applications. No matter how advanced your test equipment is, reliable contact is essential for trustworthy data. At Seiken, we transform performance requirements into reality—with tailor-made probe solutions backed by decades of experience. Need support with probing? Don’t hesitate to contact us. We’re here to help.

Our Product Lineup

Standard Lineup

Our catalog includes a variety of standard single-ended probes, ready for shipping. Dual-ended probes are typically built to order based on your specific testing conditions. We’re happy to help you select the best solution for your project.

Custom Lineup – Tailor-made solutions

Need something beyond the standard? We build custom contact probes designed for high-performance testing environments. Whether your challenges involve high currents, tight pitches, or sensitive materials, our custom probes deliver optimized solutions.

Custom solution examples

Explore more-

Others

Improvement of Current-Resistant Probes

- Electronic Component Manufacturers

- Test Houses

- Back-End Semiconductor Processes

-

Kelvin

Discrete Component Inspection Fixture

- Electronic Component Manufacturers

- Electronic Components

-

Others

Contact Probes for High-Temperature Environments

- Semiconductor Manufacturers

- Back-End Semiconductor Processes